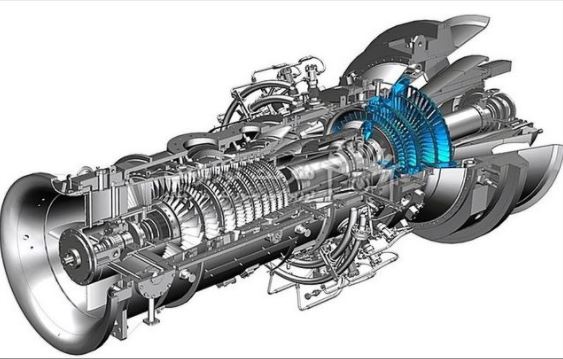

The maintenance of the gas turbine blades is important because these blades are operated in harsh conditions. Therefore, nickel-based superalloys that offer excellent performances in high-temperature conditions are typically used, and the blades are inspected and replaced based on the manufacturer’s maintenance standards. However, the service life can be extended by refurbishing the blades that have exceeded their warranty life, based on the manufacturer criteria. Turbine blades are a key component of gas-turbine maintenance and are exposed to various damage mechanisms, such as oxidation, thermal fatigue, and creep, in high-temperature and high-pressure environments. Moreover, the turbine inlet temperature is continuously increasing to maintain high efficiency. Nickel-based superalloys are typically used as blade materials because they have excellent mechanical properties, such as resistance to creep, corrosion, abrasion, and oxidation at high-temperature and high-pressure conditions. DOI 10.1007/s12206-020-1018-2.

The significant cost of replacement components has resulted in the development of repair processes to extend the life of components. One such process is full solution rejuvenation heat treatment which is intended to restore the alloy microstructure and mechanical properties to the like-new condition DOI: 10.1115/GT2017-63698.

Rejuvenation of gas turbine parts Include some steps:

*Troubleshooting; At this stage, the experts put the gas turbine under visual or expert inspection. Metallographic inspection with the help of FPI method, dimensional penetrant liquids and other EDX inspections are usually used to detect defects.

* Second step: choosing the rejuvenation method and carrying out the process. experts use many different methods to rejuvenate gas turbine parts. The method will be chosen according to the amount of damage; But in general, the following methods are used for rejuvenating parts:

1- remove of coatings and replacement of new coatings,

2-Reconstruction of all types of mechanical breakdowns,

3-Applying of rejuvenation processes,

4-advanced welding such as laser powder welding,

5-Thermal restoration.